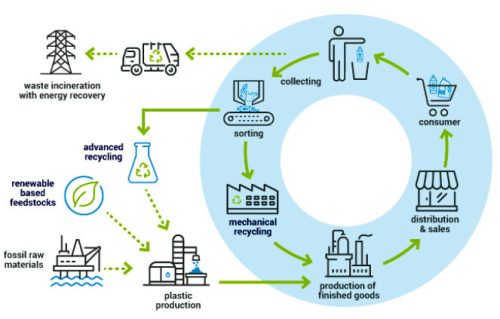

Egy lépés a fenntarthatóság felé.

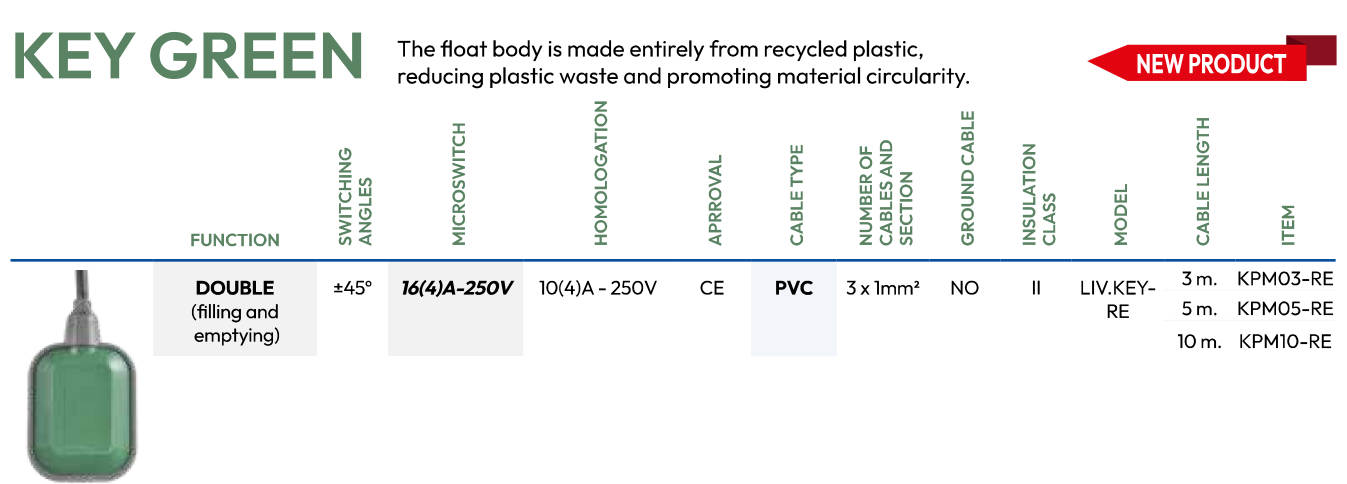

A MAC3 a műanyagipar egyik globális vezető vállalatával együttműködve bemutatja a KEY GREEN-t: a legszélesebb körben használt úszókapcsolót, amely mostantól teljes egészében újrahasznosított műanyagból készül.

Egy kézzelfogható lépés a hulladékcsökkentés és az anyagkörforgás előmozdítása felé.

Az újrahasznosított műanyagból készült Key a választás azok számára, akik a megbízhatóságot a környezeti felelősségvállalással kívánják ötvözni.

A 3×1 mm-es (3, 5, 10 méteres) kábellel, 16A mikrokapcsolóval és 250V-os feszültséggel kapható készülék a MAC3 fenntarthatóbb jövő iránti elkötelezettségének egyik példája.

Csatlakozzon a változáshoz: együtt építhetünk egy fenntarthatóbb jövőt, ahol az újrahasznosított műanyag új életre kel, hogy megvédje bolygónkat.

100%-ban Olaszországban tervezték és gyártották.

Alkalmazása

- Szivattyúállomások

- Szintszabályozás tartályokban, ciszternákban tiszta víz, esővíz és vízelvezetés esetén

- Magas szint riasztó kapcsoló

- Száraz üzemmódú védelem az alacsony szint érzékeléséhez

Műszaki adatok

Modell: KEY GREEN

Kapcsolási Szögek: ±45

Mikrókapcsoló: 16(4)A-250V

Homologáció: 10(4)A – 250V

Tanúsítvány: CE

Kábel Típus: PVC 3 x 1mm²

Föld Kábel: Nincs

Szigetelés Osztály: II

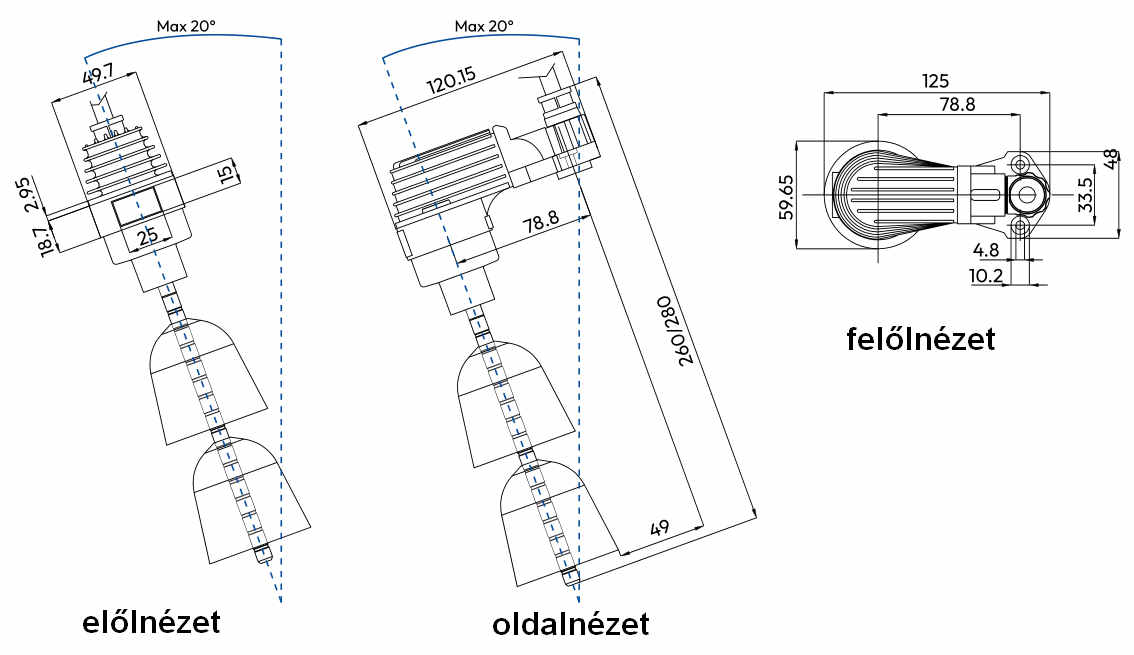

Méretek: 81 x 131 x 41.5 mm

Súly: 154 g

Védettségi fok: IP68

Maximális Folyadék Hőmérséklet: 50°C

Maximális Nyomás: 1 bar

Jellemzők

Ez az újrahasznosított műanyagból készült változat a KEY nevű úszókapcsolók családjába tartozik, amelyet a sokoldalúság és a megbízhatóság szem előtt tartásával terveztek, hogy megfeleljen a piaci igények széles körének.

Néhány megkülönböztető jellemzője a következő:

- Kábelek és mikrokapcsolók széles választéka: A kábelek és mikrokapcsolók széles választéka lehetővé teszi, hogy a KEY modellt az alkalmazás egyedi igényeinek megfelelően testre lehessen szabni.

- Kettős üzemmód a töltéshez és ürítéshez: Ez a funkció lehetővé teszi, hogy a modell könnyen alkalmazkodjon a különböző alkalmazási igényekhez, csökkentve a termékkészletet.

- Megfelelő méretek minden alkalmazástípushoz:

- A KEY modellt a különböző alkalmazások által igényelt különböző méreteket figyelembe véve tervezték, hogy minden körülmények között optimálisan használható legyen.

- Ezeknek a jellemzőknek és az aprólékos, kompromisszumok nélküli tervezésnek köszönhetően a KEY modell megbízható választást jelent a minőség és a biztonság biztosítására a különböző alkalmazásokban, mind az ivóvíz, mind a szennyvíz esetében.

Kezelési útmutató letöltése

Kezelési útmutató letöltése

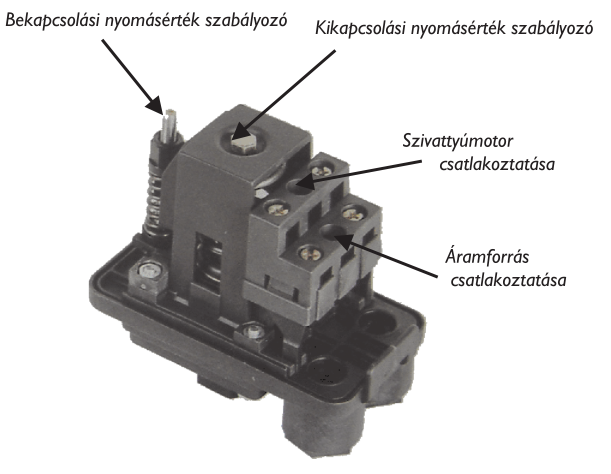

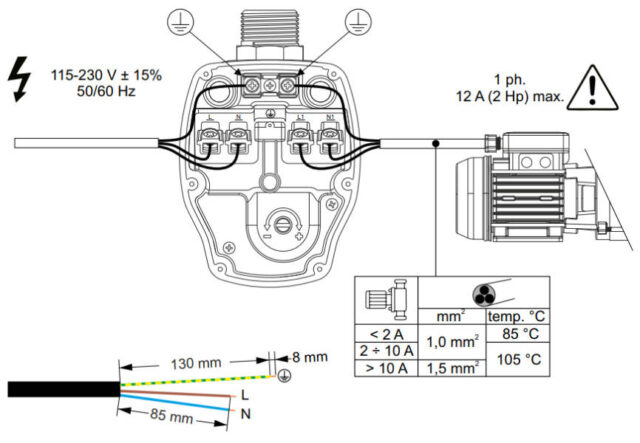

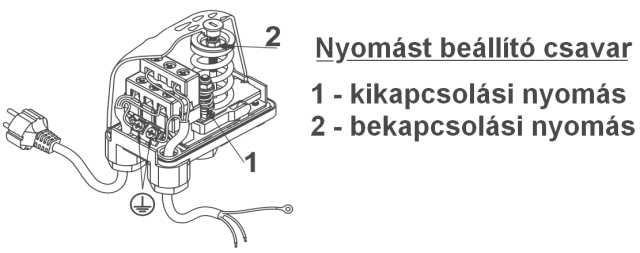

1. A készülék tetején egy műanyag csavar található. Annak kicsavarásával könnyedén leszedhetjük a burkolatot.

1. A készülék tetején egy műanyag csavar található. Annak kicsavarásával könnyedén leszedhetjük a burkolatot.

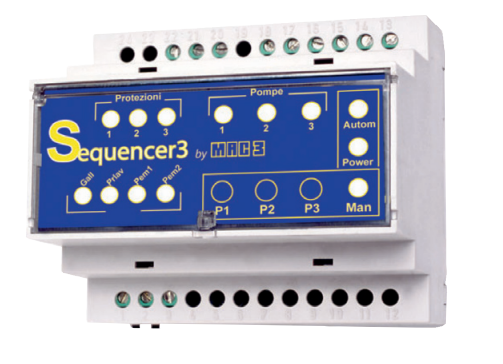

This device, thanks to the interaction with the pressure switch inserted in the circuit, permits the control and inversion of the 2 pumps in the autoclave systems. The system depends on the state of a float, which prevents its function in the absence of water.

This device, thanks to the interaction with the pressure switch inserted in the circuit, permits the control and inversion of the 2 pumps in the autoclave systems. The system depends on the state of a float, which prevents its function in the absence of water.