Application: piloting and protection of 1 submersible pump, both single and 3-phase.

Advantages: Control Panel pilots the pumps and guarantees ammetric protection, that can be regulated. It is also integrated dry running protection through the variation check of pump’s cosφ.

Benefits: No need of probes, particularly suitable for applications with deep wells. Auxiliary input for float or pressure switch.

Model DISPLAY

Power supply:

single – phase 230V±20% 50-60Hz

3 – phase 380V±10% 50 o 60Hz

Range current:

2-18A (single phase)

0,8-14A (trifase – 3phase)

Motor protection Ammetric

Interface:

Display for viewing of voltmeter, ammeter and motor Cosφ

Buttons for Automatic – off -manual

Inputs Pressure switch or floating

Approval CE

Protection rating IP55

Operating temperature – 5°C ÷ + 40 °C

Storage temperature – 20°C ÷ + 80 °C

Housing box thermoplastic

Dimensions:

19x9x24 cm (single phase)

22x12x30 cm (three phase)

Weight:

1,6 kg (single phase)

2,5 kg (three phase)

Other features:

Multilangulage

Self learning motor Cosφ

Hold timmer filling (0-250 minutes)

Sequence and phase failure protection (3-phase)

General disconecting switch with door lock

Output with cable holder

Contactor (3-pahase model)

Auxiliary circuit protection fuse

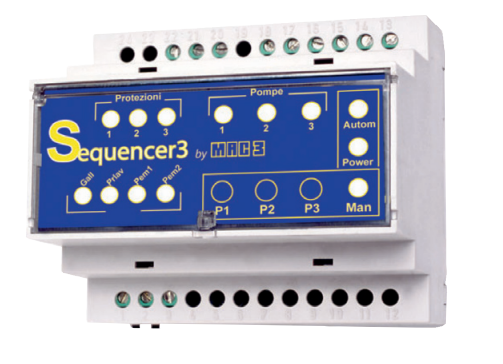

Model LED

Power supply:

single – phase 230V±20% 50-60Hz

3 – phase 380V±10% 50 o 60Hz

Range current:

2-18A (single phase)

0,8-14A (trifase – 3phase)

Motor protection Ammetric

Interface:

Flashing leds

Buttons for Automartic-off-manual

Inputs Pressure switch or floating

Approval CE

Protection rating IP55

Operating temperature – 5°C ÷ + 40 °C

Storage temperature – 20°C ÷ + 80 °C

Housing box thermoplastic

Dimensions:

14x7x19 cm (single phase)

22x12x30 cm (three phase)

Weight:

1,6 kg (single phase)

2,5 kg (three phase)

Other features:

Self learning motor Cosφ

Trimmer for adjusting the timer standby filling (0 – 100 minutes)

Dip switch for setting hold timer filling Automatic manual

Sequence and phase failure protection (3-phase)

Disconnecting switch with door lock (3-phase)

Output with cable holder

Contactor (3-phase model)

CosφAuxiliary circuit protection fuse

This device, thanks to the interaction with the pressure switch inserted in the circuit, permits the control and inversion of the 2 pumps in the autoclave systems. The system depends on the state of a float, which prevents its function in the absence of water.

This device, thanks to the interaction with the pressure switch inserted in the circuit, permits the control and inversion of the 2 pumps in the autoclave systems. The system depends on the state of a float, which prevents its function in the absence of water.